Basic mandrels and More

Tube bending has come a long way since wet-packed sand cerrobend or cable mandrels. In addition to the basic mandrels described below, TFB has designed these and many other specialty hybrid materials: hydroforming, wave guide, tube-within-a-tube, bend-on-a-bend, sizing, bullet-nosed, plastic, and sheathed materials.

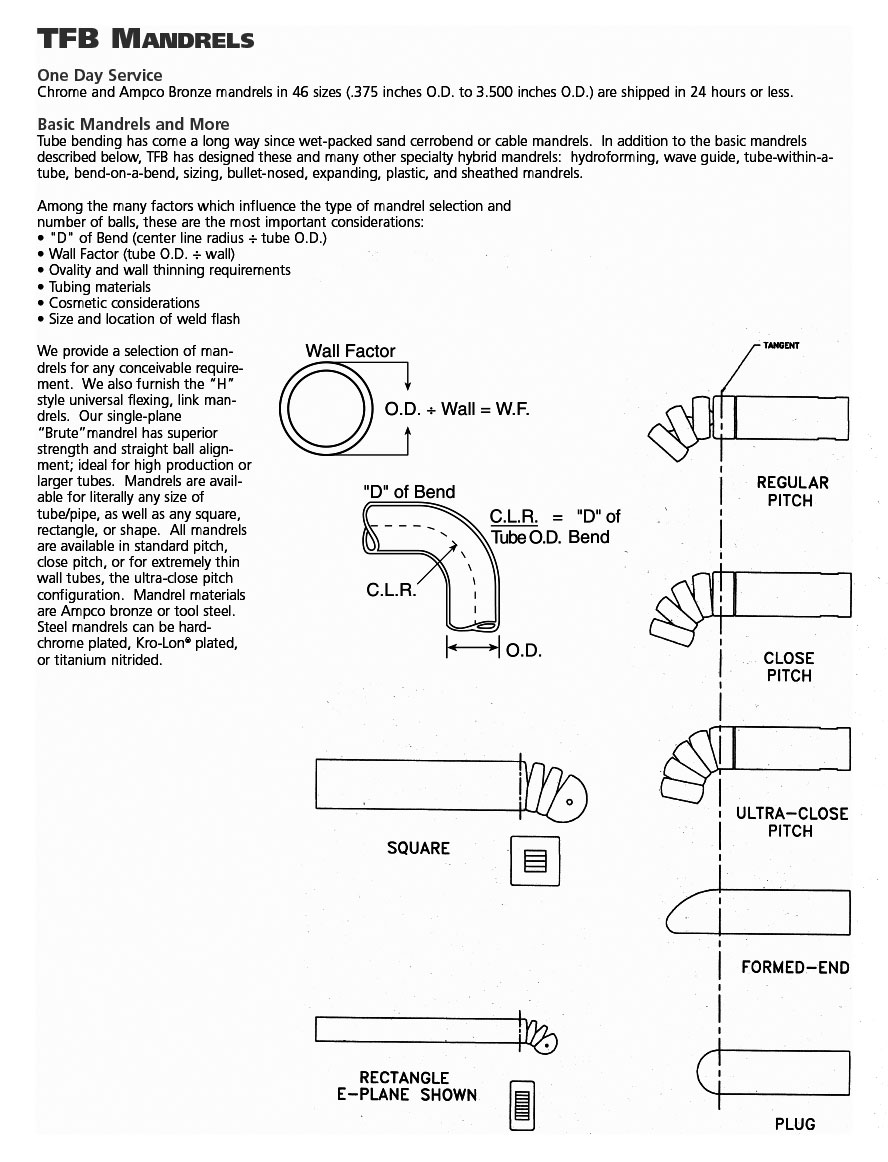

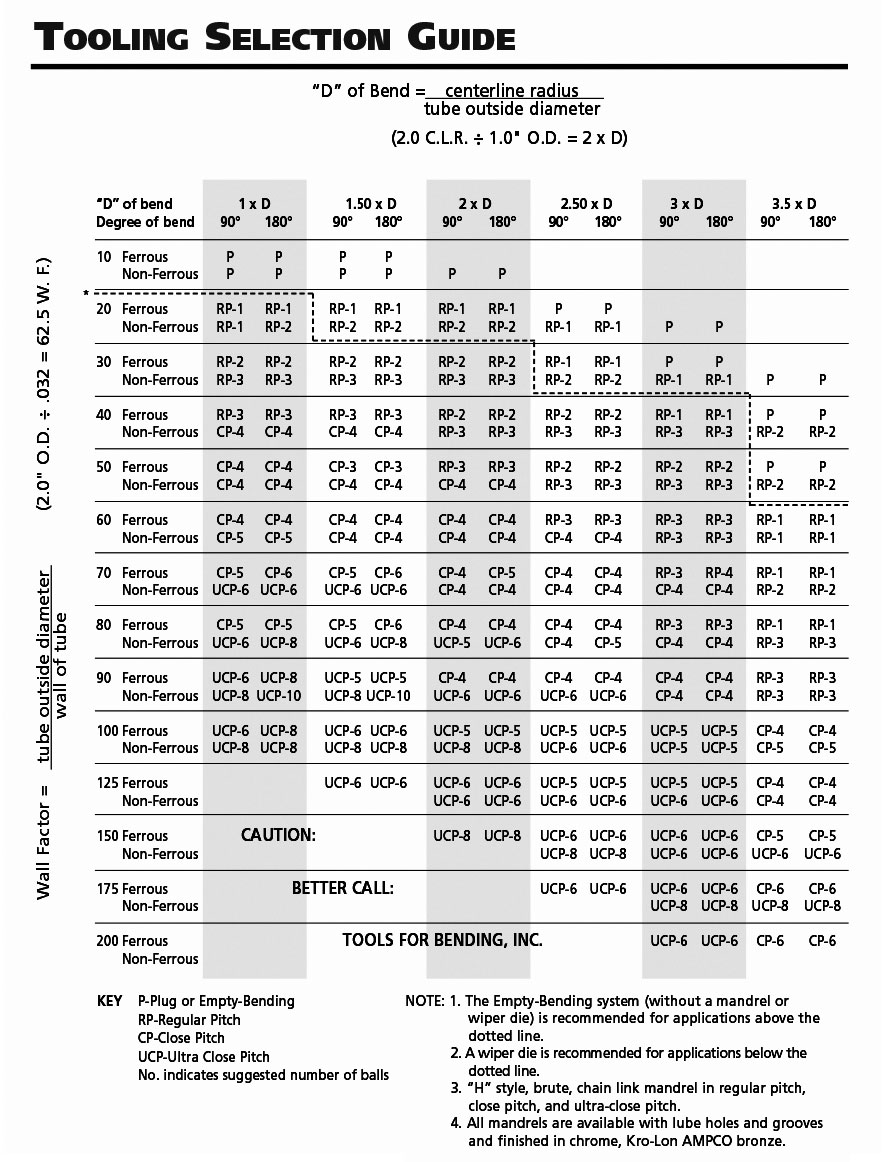

Among the many factors which influence the type of mandrel selection and number of balls, these are the most important considerations:

- “D” of Bend (center line radius ÷ tube O.D.)

- Wall Factor (tube O.D. ÷ wall)

- Ovality and wall thinning requirements

- Tubing materials

- Cosmetic considerations

- Size and location of weld flash

We provide a selection of mandrels for any conceivable requirement. We also furnish the “H” style universal flexing, link mandrels. Our single-plane “Brute” mandrel has superior strength and straight ball alignment; ideal for high production or larger tubes. Mandrels are available for literally any size of tube/pipe, as well as any square, rectangle, or shape. All mandrels are available in standard pitch, close pitch, or for extremely thin wall tubes, the ultra-close pitch configuration. Mandrel materials are bronze or tool steel. Steel mandrels can be hard-chrome plated, Kro-Lon® plated, or titanium nitrided.

One Day Service

Chrome and Bronze mandrels in 46 sizes (.375″ O.D. to 3.0″ O.D.) are shipped in 24 hours or less.