Assembly & Disassembly of “H” 5&6 (Popet-Link) Type Regular Mandrels

Disassembly

- 1. Use a long Allen Wrench (12) and remove Shank Link Cap Screw (11). Ball assembly, complete with Shank Link (9) can now be withdrawn from Shank (10).

- 2. Detent Spring & Ball (6) will release from Center Link’s cavity. Be careful not to lose them.

- 3. Spread Snap Ring (7) apart with snap ring pliers and pry out.

- 4. To release Center Ball (8) from Center Link (5) insert two shims on opposing edges of Center Ball. Place Assembly, face down, in divided vise, opening being the same width as the diameter of the End Ball. Apply sufficient pressure with a rubber mallet to the spherical end to “pop” the center ball off the flat surface of the center link.

- 5. Remove the Detent Ball and Spring (3) form the End Link’s cavity.

- 6. Bend back Center Link over spherical end of End Link approximately 90o, then “pop” off using pliers.

- 7. To disassemble the End Ball (2) and End Link (1) repeat the procedure. Since the end ball is glued to the end link, it may be necessary to strike the spherical end a little harder to “break” the seal.

Assembly:

To reassemble, reverse this procedure, using a high quality clean lubricating oil between all mating surfaces and in the detent spring bore.

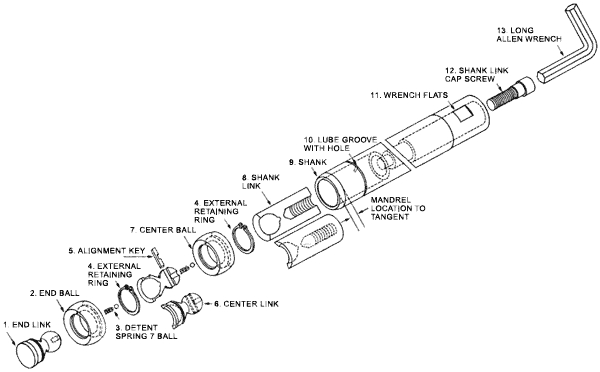

Assembly & Disassembly of “H” 5&6 (Split-Link) Regular & Close Pitch Mandrels

Disassembly

- Use a long Allen Wrench (13) and remove Shank Link Cap Screw (12). Ball Assembly, complete with Shank Link (8) can now be withdrawn from Shank (9).

- Remove the Retaining Ring (4); to prevent damage to the ring, only use the proper size external ring pliers.

- The Ball (7) can now be removed from the Center Link (6). The Center Link (6), like the Shank Link (8), are machined in exact halves; it is always a good practice to keep matched links wired together and don’t lose the detent spring and ball.

Assembly:

To re-assemble, reverse this procedure, using a high quality, clean lubricating oil between all mating surfaces and in the detent spring bore.